Aql Tables Special Inspection Levels While the general inspection levels determine the sample size for your inspection overall, the special levels (s 1, s 2, s 3, s 4) are used only for specific items on your inspection checklist. using the special levels gives you a smaller sample size, which may be appropriate for some tests. Three inspection levels, i, ii and iii, are given in table 1 for general use. unless otherwise specified, level ii shall be used. level i may be used when less discrimination is needed or level iii when greater discrimination is required.

Aql Tables Special Inspection Levels How to choose the special inspection levels from the aql table? what's the difference between the general and special inspection levels of the aql table?. Acceptable quality limit table refers to the ansi asq z1.4 table used by qc inspections professionals for aql sampling during the inspection. this aql sampling plan is designed to help in determining the right sample size for inspection and the acceptable number of defects. The general and special inspection levels of the aql table determine the sample sizes for inspection. find out each sample size role and differences!. Our experts will guide you in selecting the inspection level and aql values that best fit your requirements. use our aql sampling calculation tool to simulate product inspections and gain a better understanding of how the process works.

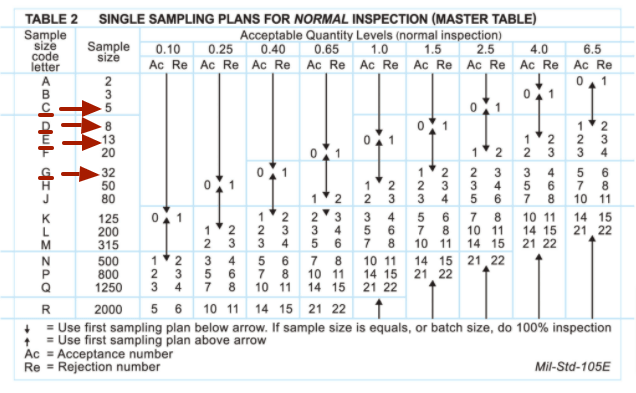

Aql Tables Special Inspection Levels The general and special inspection levels of the aql table determine the sample sizes for inspection. find out each sample size role and differences!. Our experts will guide you in selecting the inspection level and aql values that best fit your requirements. use our aql sampling calculation tool to simulate product inspections and gain a better understanding of how the process works. Three general and four special inspection levels are provided. the general inspection levels (i to iii) are commonly used for non destructive inspection. level ii is considered the norm (except for small sample sizes). level i is required only 40 percent of inspection level ii and can be used where less discrimination is needed. The general inspection level is used to determine the sample size for workmanship check and specification conformity verification, while the special inspection level is used to determine the sample size for special tests in aql inspection. You may have noticed that the second column on table 1 features four so called ‘special inspection levels’. selecting one of these levels will lead to a smaller sample being examined. answers to some of the most common questions & concerns. what is the defect classification?. When you refer to the aql chart, you’ll encounter two types of inspection levels—general and special. understanding the distinct roles of the general and special inspection levels equips you with the knowledge to make informed decisions about your inspections.

Inspection Standard Aql Tables China Inspection Services China Three general and four special inspection levels are provided. the general inspection levels (i to iii) are commonly used for non destructive inspection. level ii is considered the norm (except for small sample sizes). level i is required only 40 percent of inspection level ii and can be used where less discrimination is needed. The general inspection level is used to determine the sample size for workmanship check and specification conformity verification, while the special inspection level is used to determine the sample size for special tests in aql inspection. You may have noticed that the second column on table 1 features four so called ‘special inspection levels’. selecting one of these levels will lead to a smaller sample being examined. answers to some of the most common questions & concerns. what is the defect classification?. When you refer to the aql chart, you’ll encounter two types of inspection levels—general and special. understanding the distinct roles of the general and special inspection levels equips you with the knowledge to make informed decisions about your inspections.