Overview On Kanban Methodology And Its Implementation Pdf Business Kanban is also known as the toyota nameplate system in the automotive industry. a goal of the kanban system is to limit the buildup of excess inventory at any point in production. limits on the number of items waiting at supply points are established and then reduced as inefficiencies are identified and removed. Kanban is an agile management method built on a philosophy of continuous improvement, where work items are “pulled” from a product backlog into a steady flow of work. the framework is applied using kanban boards, a form of visual project management. in a kanban board, tasks—represented as cards—move through stages of work—represented as columns.

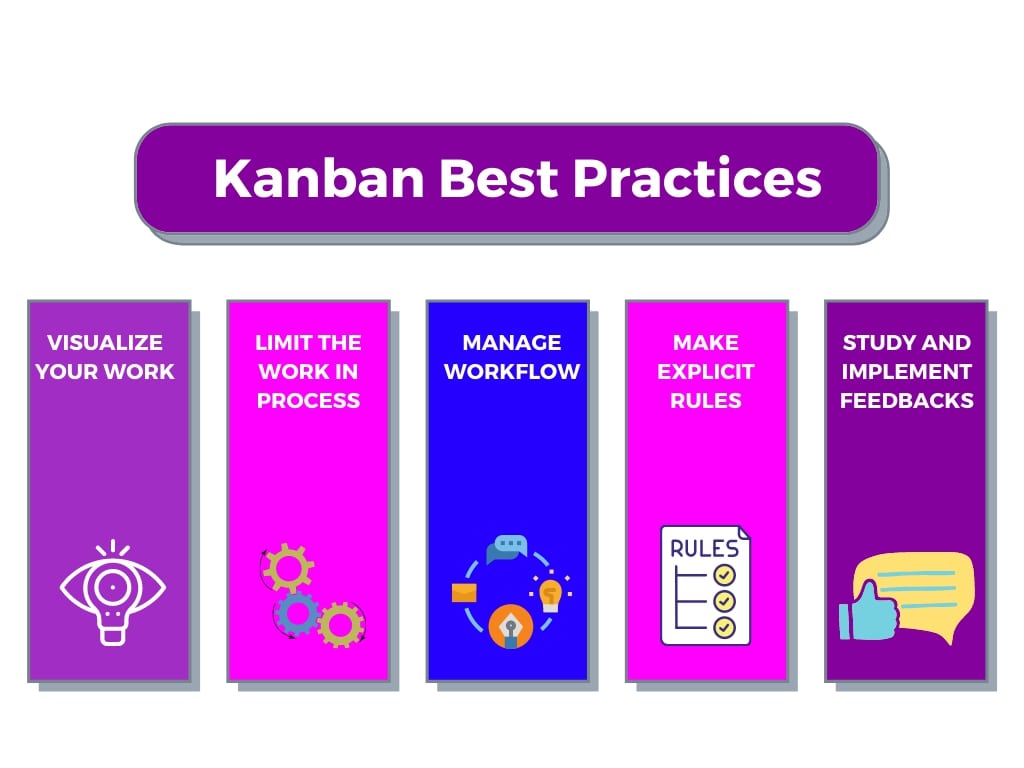

Kanban Methodology Infographics By Slidesgo Pdf Planets Planets The kanban method is an approach to evolutionary and incremental systems and process change for organizations. a work in progress limited pull system is the central mechanism to uncover system operation (or process) complications and encourage collaboration to continuously improve the system. Kanban is one of the most popular lean workflow management methods for defining, managing, and improving services that deliver knowledge work. it helps you visualize work, maximize efficiency, and improve continuously. Kanban is a systematic method of work, derived from lean and agile. it ensures teams pull work items kanban cards through a process, achieving continuous delivery. Kanban, derived from the japanese term meaning “visual signal” or “card,” is defined as a powerful visual project management and workflow optimization tool.

The Implementation Of An Integrated Kanban System In A Business Can Be Kanban is a systematic method of work, derived from lean and agile. it ensures teams pull work items kanban cards through a process, achieving continuous delivery. Kanban, derived from the japanese term meaning “visual signal” or “card,” is defined as a powerful visual project management and workflow optimization tool. Kanban is a project management methodology that allows project managers to visualize their team’s work on easy to use boards that facilitate the process of planning, scheduling and tracking work. by using the kanban method, project managers have full transparency in the task management process. Kanban is a visual work management system that provides a clear representation of work progression within a process. it offers a visual depiction of both the workflow process and the tasks in transit. Kanban is a widely used framework for managing workflows and improving efficiency in project management. kanban originated from toyota’s lean manufacturing system and evolved into a flexible framework that helps teams visualize work, manage tasks, and deliver value continuously. Kanban is an inventory control system used in just in time (jit) manufacturing. it was developed by taiichi ohno, an industrial engineer at toyota, and takes its name from the colored cards.

Kanban Methodology Complete Guide To Kanban Methodology Kanban is a project management methodology that allows project managers to visualize their team’s work on easy to use boards that facilitate the process of planning, scheduling and tracking work. by using the kanban method, project managers have full transparency in the task management process. Kanban is a visual work management system that provides a clear representation of work progression within a process. it offers a visual depiction of both the workflow process and the tasks in transit. Kanban is a widely used framework for managing workflows and improving efficiency in project management. kanban originated from toyota’s lean manufacturing system and evolved into a flexible framework that helps teams visualize work, manage tasks, and deliver value continuously. Kanban is an inventory control system used in just in time (jit) manufacturing. it was developed by taiichi ohno, an industrial engineer at toyota, and takes its name from the colored cards.

What Is Kanban Methodology Introduction To Kanban Framework 52 Off Kanban is a widely used framework for managing workflows and improving efficiency in project management. kanban originated from toyota’s lean manufacturing system and evolved into a flexible framework that helps teams visualize work, manage tasks, and deliver value continuously. Kanban is an inventory control system used in just in time (jit) manufacturing. it was developed by taiichi ohno, an industrial engineer at toyota, and takes its name from the colored cards.

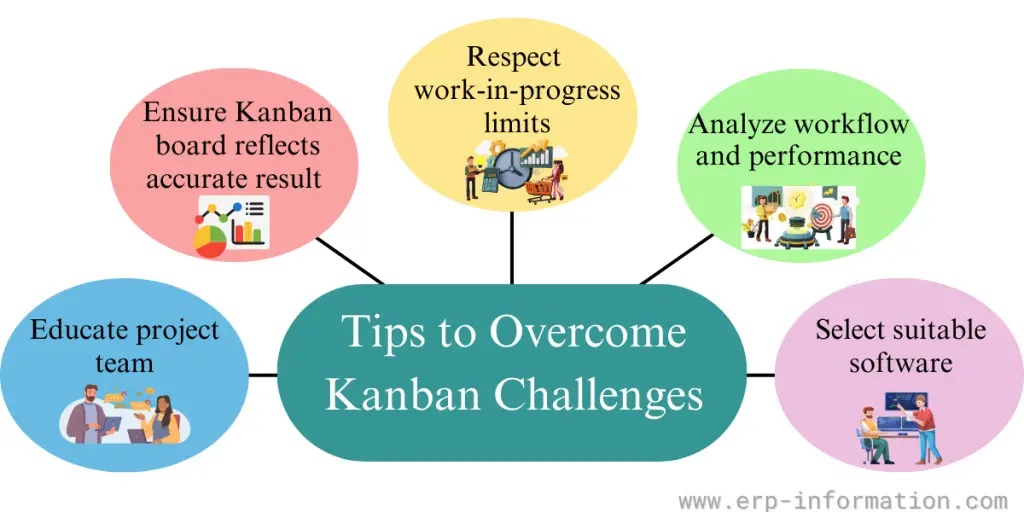

Kanban Methodology Meaning Implementation Challenges