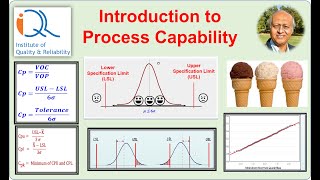

Pdf Process Capability Cp Cpk Pp Ppk Compress Pdf Process capability and performance (pp, ppk, cp, cpk) are specification indicators relative to process dispersion and process centering. process capability is a statistical measurement of a process’s ability to produce parts within specified limits consistently. Process capability measures how consistently a manufacturing process can produce parts within specifications. the basic idea is very simple. you want your manufacturing process to: (1) be centered over the nominal desired by the design engineer, and. (2) with a spread narrower than the specification width.

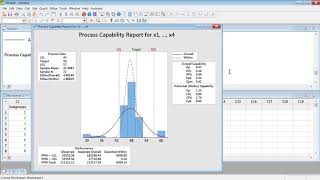

Process Capability What Is Cp Cpk Pp Ppk Presentationeze Pdf We will explore how this analysis, through the computation of cp and cpk values, provides a deeper understanding of a process’s capability, both in terms of meeting specifications and maintaining target alignment. Cpk is used as a statistical measure to assess the capability of a manufacturing process to produce products within specified tolerance limits, providing a quantifiable indication of process performance and consistency. The difference between the centralized rates (cp and pp) and unilateral rates (cpk and ppk) is the impact of the mean decentralization over process performance estimates. Process capability gives you a deep view into how well your process performs. by calculating cp, cpk, and related indices, you gain insights into variation, centering, and potential improvements.

Process Capability Explaining Cp Cpk Pp Ppk And How To Interpret Those The difference between the centralized rates (cp and pp) and unilateral rates (cpk and ppk) is the impact of the mean decentralization over process performance estimates. Process capability gives you a deep view into how well your process performs. by calculating cp, cpk, and related indices, you gain insights into variation, centering, and potential improvements. Cp and cpk help to estimate how well a process characteristic meets specification requirements. this article presents the idea of process capability, useful formulas, result interpretation, and recommendations for proper use. Process capability is the degree to which a process can repeatedly produce parts or products that meet the required specifications. a capable process will produce products that comply with the specifications. the capability index is a measure to show how capable the process is. The main difference between cp and cpk is that cp only considers the spread of the process data relative to the specification limits, while cpk also considers the location of the process average relative to the specification limits.

Process Capability Explaining Cp Cpk Pp Ppk And How To Interpret Those Cp and cpk help to estimate how well a process characteristic meets specification requirements. this article presents the idea of process capability, useful formulas, result interpretation, and recommendations for proper use. Process capability is the degree to which a process can repeatedly produce parts or products that meet the required specifications. a capable process will produce products that comply with the specifications. the capability index is a measure to show how capable the process is. The main difference between cp and cpk is that cp only considers the spread of the process data relative to the specification limits, while cpk also considers the location of the process average relative to the specification limits.