Air Cooled Industrial Chillers Air Cooled Scroll Chillersä Senho Chiller Senho air cooled chillers feature convenient installation and easy maintenance. with generously sized epoxy coated aluminum condenser and strong axial fans for heat removal, they perform reliably & powerfully under heavy duty working conditions. Whether you need a stationary air cooled chiller, portable air cooled chiller or central air cooled chiller, cold shot chillers® has the solution to all your air cooled industrial chiller needs.

Water Cooled Chillers Leading Industrial Chiller Manufacturerä Senho Air cooled portable chillers are widely applied in small and medium scale cooling project, such as one to one cooling in plastic industry, food and beverage industry, laser industry, etc. models within pra03~pra20 are equipped with casters for relocation. We offer both air cooled and water cooled industrial chillers that have a wide range of cooling capacity from 10 tons to 500 tons. our chiller rentals are perfect for keeping your warehouses, data centers, industrial spaces, concert spaces or construction sites cool and dry. Air cooled central chillers discover senho's range of high capacity air cooled central chillers, spanning 105kw to 928kw, with efficient screw compressors. ideal for large scale cooling needs or comprehensive central cooling systems. upgrade your cooling solution today. learn more. Chillers with air cooled condensers utilize air to refrigerant heat exchangers, while water cooled chillers reject the heat via cooling tower or dry cooler. an air cooled condenser uses ambient air for cooling and condensing the refrigerant gas back to a liquid.

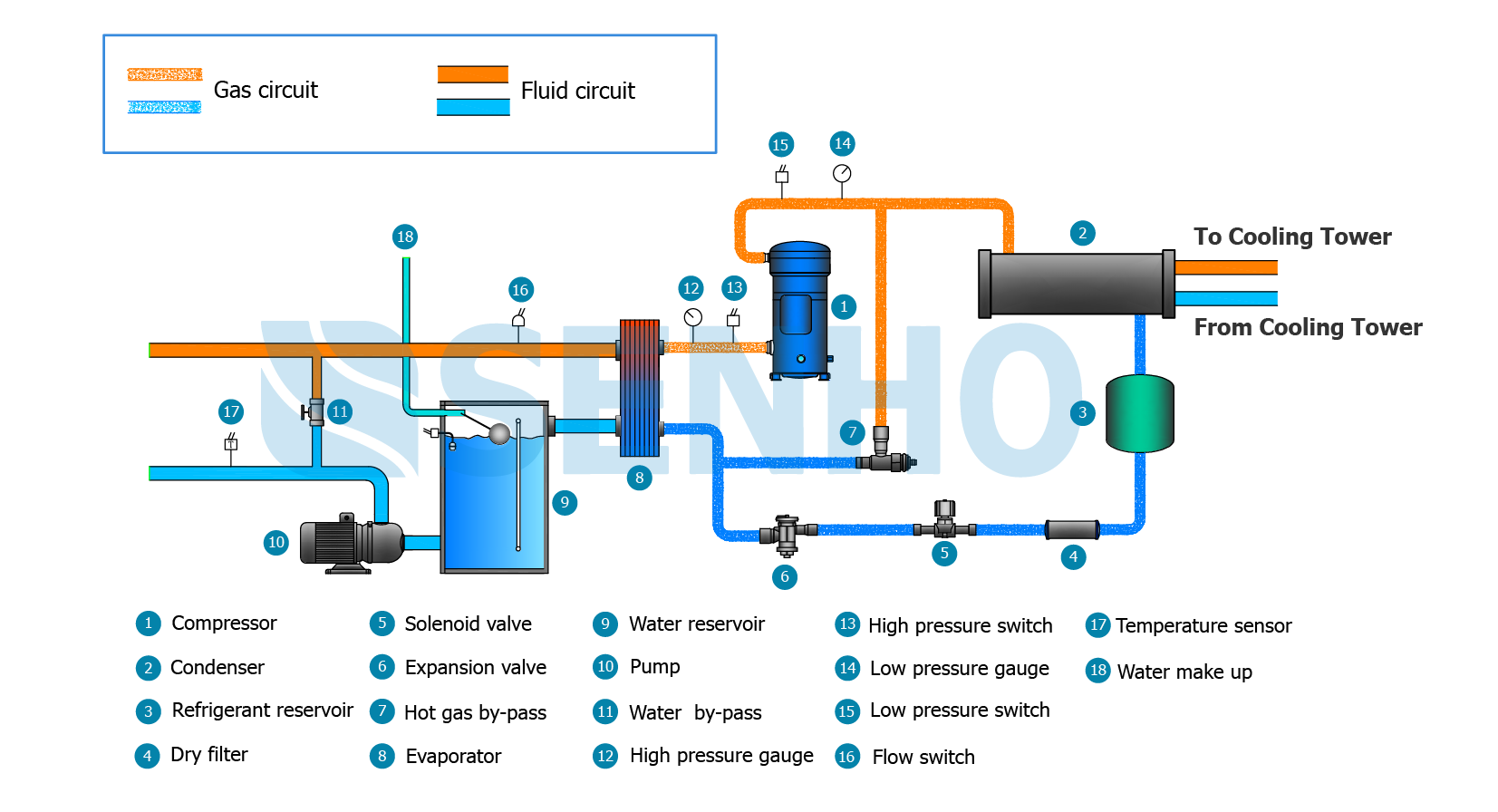

Air Cooled Water Chillers Air Cooled Type Chillersä Senho Chiller Air cooled central chillers discover senho's range of high capacity air cooled central chillers, spanning 105kw to 928kw, with efficient screw compressors. ideal for large scale cooling needs or comprehensive central cooling systems. upgrade your cooling solution today. learn more. Chillers with air cooled condensers utilize air to refrigerant heat exchangers, while water cooled chillers reject the heat via cooling tower or dry cooler. an air cooled condenser uses ambient air for cooling and condensing the refrigerant gas back to a liquid. Air cooled chillers use ambient air to cool the refrigerant, while water cooled chillers use a water source like a cooling tower. water cooled chillers are generally more efficient but require a reliable water supply and more maintenance. There are two main types: air cooled and water cooled chillers. both do the same job, but they go about it differently. both air cooled and water cooled chillers remove heat from your process, but how they do it (and which one fits your setup) depends on a few key factors:. Water cooled chillers reject heat using water circulated through a cooling tower, while air cooled chillers use ambient air and fans to dissipate heat via condenser coils. the choice between these types depends on factors like cooling load, available resources, space constraints, budget, and environmental considerations. What is the difference between an air cooled vs water cooled chiller, and see how chillers work including the refrigerant circuit for each.