Top Industrial Applications In Robotic Applications Pdf Robot Industrial robots are now a common sight in numerous factories, warehouses, and sectors worldwide. discover the many ways in which they are used today. In this post, we'll cover the top 12 industrial robot applications that are shaping the present. you'll learn how these automated machines are reshaping productivity and efficiency across multiple industries.

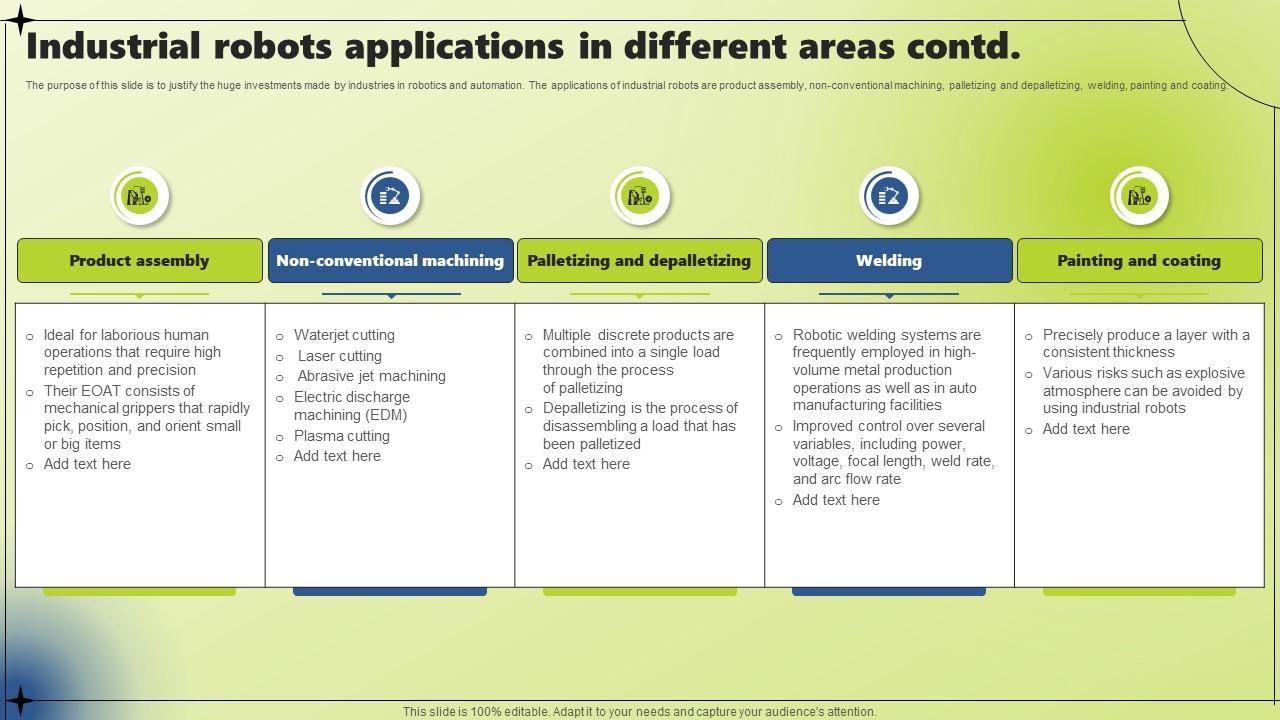

Applications Of Industrial Robotic Systems Industrial Robots We’ll walk you through common robot types, from traditional industrial robots to cutting edge collaborative and mobile robots. by the end, you’ll better understand the applications of these robots and how they can help boost productivity, streamline workflows, and enhance safety in your industry. Industrial robots resemble humans, consisting of multiple joints, articulations, and manipulators that are programmable and work together to execute a specific task efficiently and quickly. additionally, industrial robots also help to achieve cost synergies and reduce wastage. Here are the specific tasks traditional industrial robots are designed to perform: 1. arc welding. arc welding, or robot welding, became commonplace in the 1980s. one of the driving forces for switching to robot welding is improving the safety of workers from arc burn and inhaling hazardous fumes. 2. spot welding. As the industrial landscape undergoes a digital transformation, these robots are at the forefront, offering various types and applications of robotic automation that cater to different manufacturing needs in the assembly line.

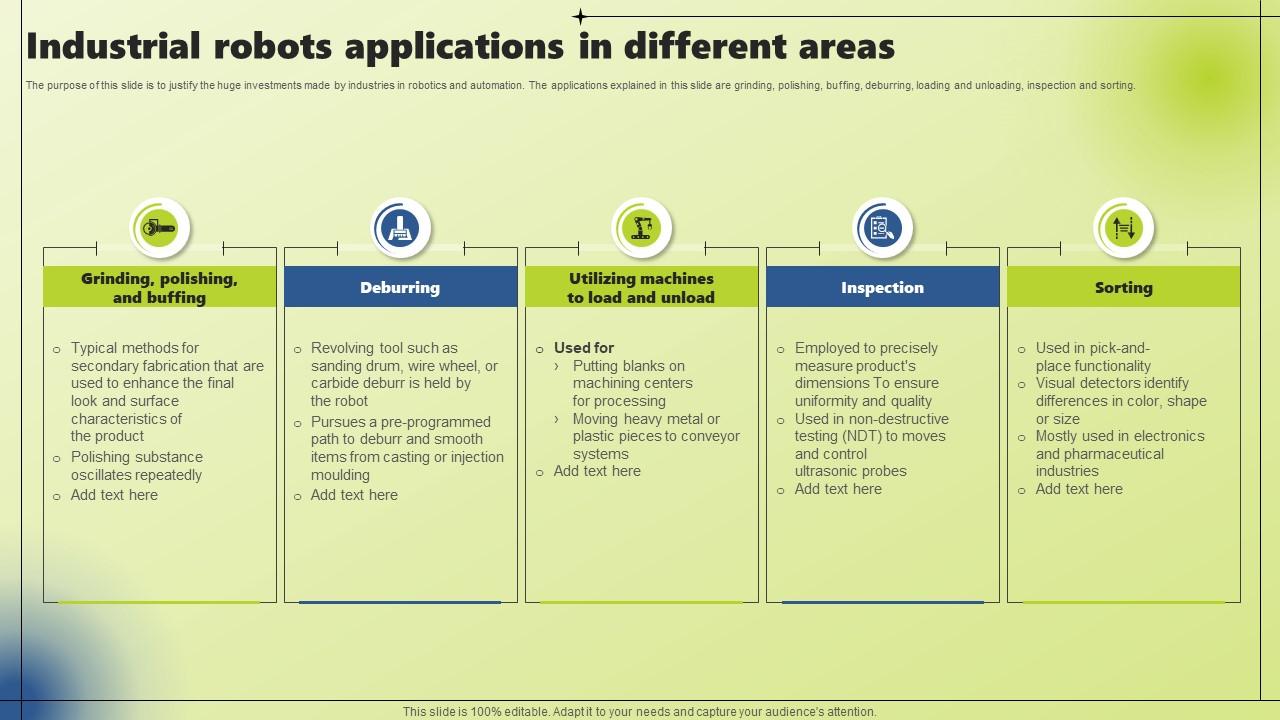

Applications Of Industrial Robotic Systems Industrial Robots Here are the specific tasks traditional industrial robots are designed to perform: 1. arc welding. arc welding, or robot welding, became commonplace in the 1980s. one of the driving forces for switching to robot welding is improving the safety of workers from arc burn and inhaling hazardous fumes. 2. spot welding. As the industrial landscape undergoes a digital transformation, these robots are at the forefront, offering various types and applications of robotic automation that cater to different manufacturing needs in the assembly line. From welding and cutting to assembling and sorting, industrial robots are transforming manufacturing processes with unmatched efficiency and precision. this article explores 13 essential applications of industrial robots, showcasing their impact on productivity and safety. At its core, an industrial robot is an automatically controlled, reprogrammable, multi purpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications. Industrial robot systems deliver numerous economic and intangible benefits, including higher process efficiency, improved product quality, and streamlined workflows. Here are the top 5 applications for industrial robots: material handling is the most popular application with 38% of operational stock of industrial robots worldwide. this includes robotic machine tending, palatalizing and various operations for metal machining and plastic moulding.

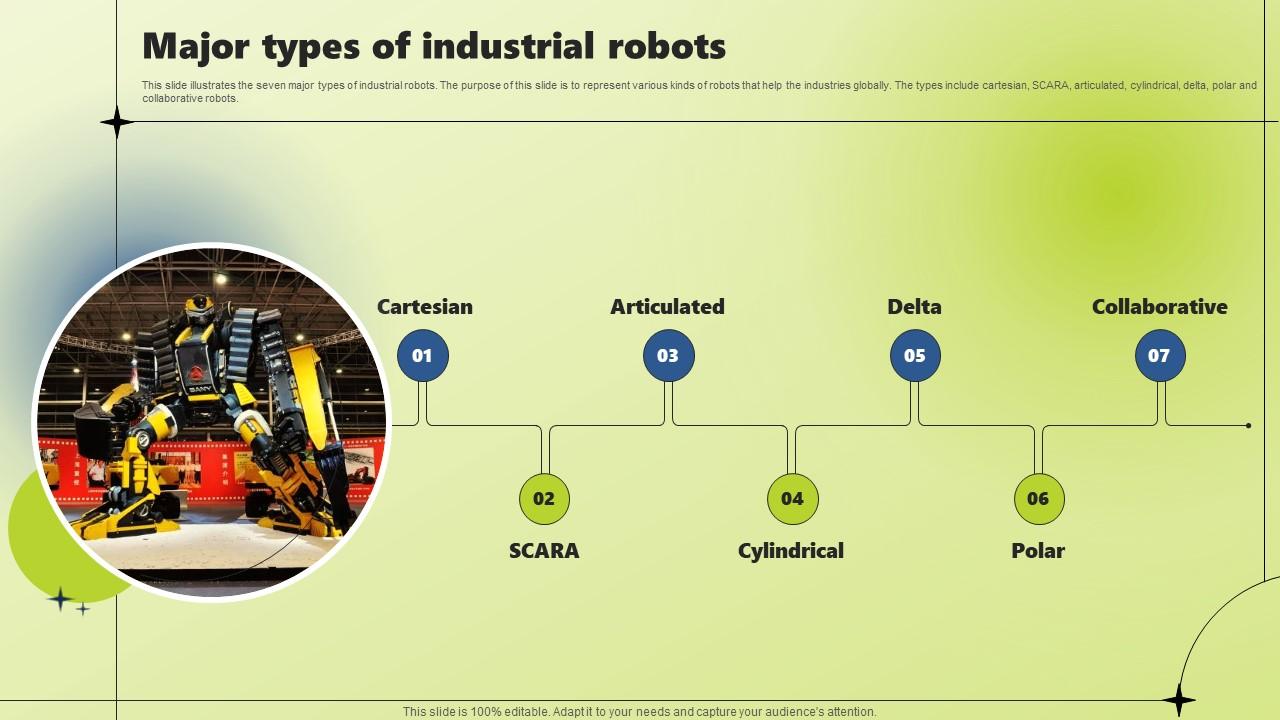

Applications Of Industrial Robotic Systems Major Types Of Industrial From welding and cutting to assembling and sorting, industrial robots are transforming manufacturing processes with unmatched efficiency and precision. this article explores 13 essential applications of industrial robots, showcasing their impact on productivity and safety. At its core, an industrial robot is an automatically controlled, reprogrammable, multi purpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications. Industrial robot systems deliver numerous economic and intangible benefits, including higher process efficiency, improved product quality, and streamlined workflows. Here are the top 5 applications for industrial robots: material handling is the most popular application with 38% of operational stock of industrial robots worldwide. this includes robotic machine tending, palatalizing and various operations for metal machining and plastic moulding.

Industrial Robots For Various Applications Universal Robotic Inc Industrial robot systems deliver numerous economic and intangible benefits, including higher process efficiency, improved product quality, and streamlined workflows. Here are the top 5 applications for industrial robots: material handling is the most popular application with 38% of operational stock of industrial robots worldwide. this includes robotic machine tending, palatalizing and various operations for metal machining and plastic moulding.

Industrial Robots Challenges And Possible Solutions Applications Of