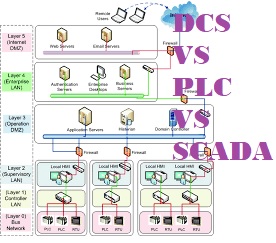

Difference Between Scada Plc And Dcs Pdf Programmable Logic We can control any electrical equipment according to us with the help of plc, to do this we only have to do programming in the software of plc, after that the device starts running according to the way we have programmed it. the full form of scada is supervisory control and data acquisition (supervisory control and data acquisition). Plcs are used for control and monitoring purposes, while scada systems are used for visualization and operator interface. plcs are more specific and localized while scada is more general and centralized.

Plc Vs Scada Archana Automation Scada stands for supervisory control and data acquisition, as the name indicates the scada system supervises, acquires, and controls the data which is received from a distant data source from the control center. Data management and processing capabilities differ between plc and scada systems, reflecting their distinct roles in industrial automation. plc (programmable logic controller): plcs are designed for real time control tasks, processing input data from sensors and generating output signals for actuators based on the control logic defined in the. Plcs focus on immediate control and response, while scada focuses on monitoring, data analysis, and long term oversight. scada systems use hmis to allow operator interaction, while plcs typically require separate programming software for interaction. Plcs are best suited for controlling discrete processes, whereas scada systems are best suited for process control applications requiring a high degree of automation. the choice between plcs and scada systems is determined by the application’s particular requirements.

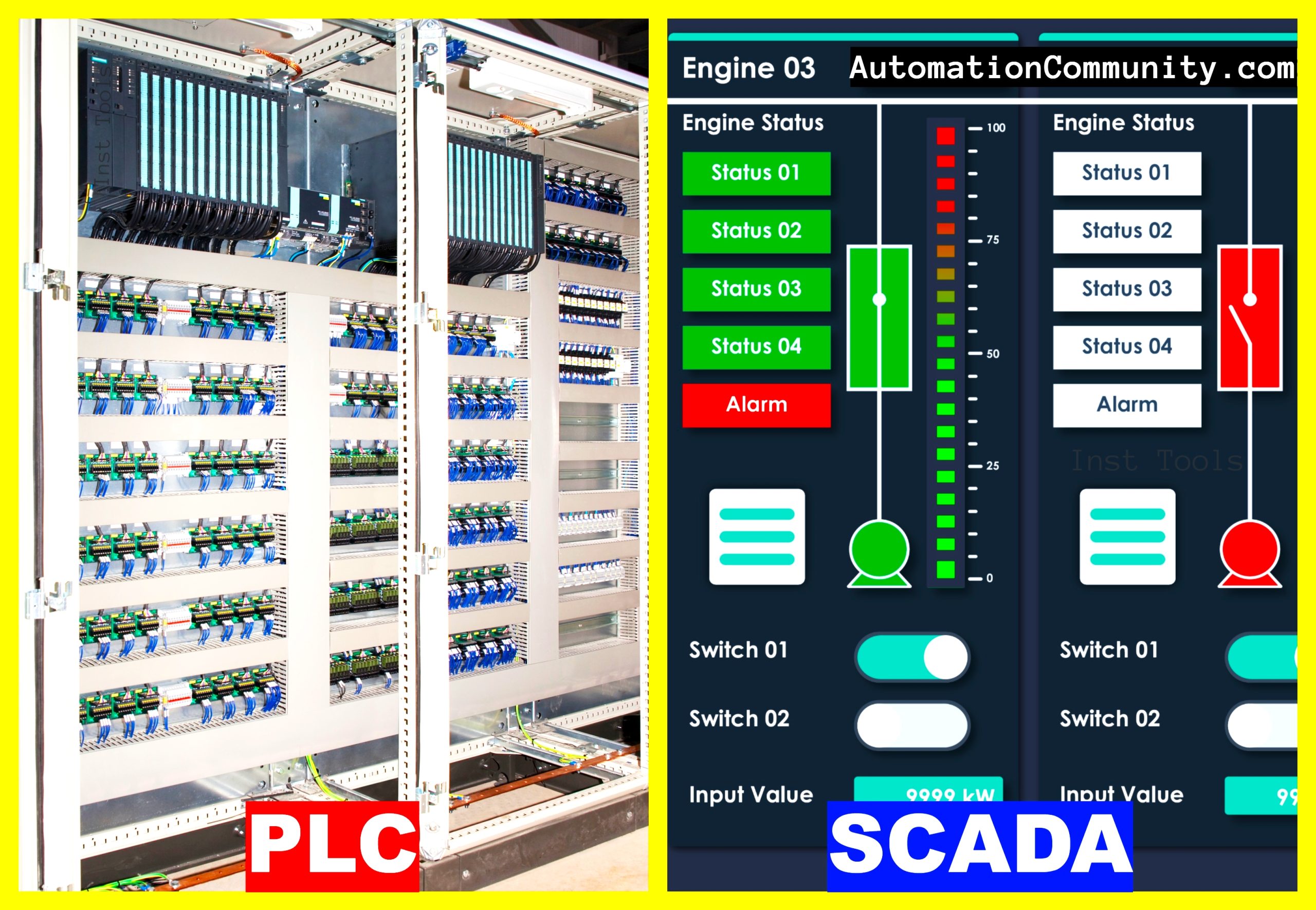

Difference Between Plc And Scada Automation Community Plcs focus on immediate control and response, while scada focuses on monitoring, data analysis, and long term oversight. scada systems use hmis to allow operator interaction, while plcs typically require separate programming software for interaction. Plcs are best suited for controlling discrete processes, whereas scada systems are best suited for process control applications requiring a high degree of automation. the choice between plcs and scada systems is determined by the application’s particular requirements. The difference between them is that the plc is hardware based and scada is software based. while both fall under the category of “control systems”, scada provides greater capability than the plc with the help of several components. Scada and plc systems are the backbone of industrial automation, each playing a unique but complementary role. scada excels at system wide monitoring, data analysis, and centralized control, while plc handles localized, real time execution of tasks. Discover the key difference between plc and scada systems in our complete guide. learn how these technologies work, their applications, benefits, and how they complement each other in industrial automation. Plc is the “muscle” of the operation, executing specific control tasks such as starting and stopping machinery or adjusting valve positions based on predefined logic. scada, on the other hand, acts as the “brain,” providing operators with comprehensive monitoring and control capabilities for the entire system.

Perbedaan Plc Scada Dcs Elektronika Pdf The difference between them is that the plc is hardware based and scada is software based. while both fall under the category of “control systems”, scada provides greater capability than the plc with the help of several components. Scada and plc systems are the backbone of industrial automation, each playing a unique but complementary role. scada excels at system wide monitoring, data analysis, and centralized control, while plc handles localized, real time execution of tasks. Discover the key difference between plc and scada systems in our complete guide. learn how these technologies work, their applications, benefits, and how they complement each other in industrial automation. Plc is the “muscle” of the operation, executing specific control tasks such as starting and stopping machinery or adjusting valve positions based on predefined logic. scada, on the other hand, acts as the “brain,” providing operators with comprehensive monitoring and control capabilities for the entire system.

Dcs Vs Plc Vs Scada Engineerswikis Discover the key difference between plc and scada systems in our complete guide. learn how these technologies work, their applications, benefits, and how they complement each other in industrial automation. Plc is the “muscle” of the operation, executing specific control tasks such as starting and stopping machinery or adjusting valve positions based on predefined logic. scada, on the other hand, acts as the “brain,” providing operators with comprehensive monitoring and control capabilities for the entire system.

Plc Vs Scada Difference Between Plc And Scada Vrogue Co