Process Control Ppt 4 Pdf Complete the following steps to interpret a normal capability analysis. key output includes the histogram, normal curves, and capability indices. your process should be stable and the original (or transformed) process data should follow a normal distribution. Use capability analysis to determine whether your process meets customer requirements. to add output from a capability analysis, go to add and complete a form. use normal capability analysis to evaluate the potential (within) and overall capability of your process based on a normal distribution.

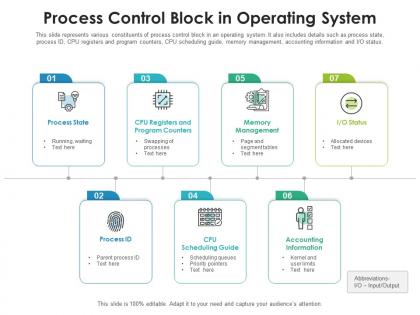

Process Control Block Powerpoint Presentation And Slides Ppt Example Complete the following steps to interpret a capability analysis. key output includes the histogram and capability indices. while the analysis selects a method that fits the sample data, assess your data for any problems to follow good practice. for example, investigate outliers in the data that reveal process behavior that you don't understand. Master minitab's process capability sixpack! easily assess process & ensure you're meeting specs in 4 steps. Therefore, the assumptions for normal capability analysis are satisfied and the capability of the process can be analyzed. the histogram and capability indices indicate that the process is approximately centered on the target and the measurements are within the specification limits. Control charts are graphs that plot your process data in time ordered sequence. most control charts include a center line, an upper control limit, and a lower control limit.

Process Control Block Powerpoint Presentation And Slides Ppt Example Therefore, the assumptions for normal capability analysis are satisfied and the capability of the process can be analyzed. the histogram and capability indices indicate that the process is approximately centered on the target and the measurements are within the specification limits. Control charts are graphs that plot your process data in time ordered sequence. most control charts include a center line, an upper control limit, and a lower control limit. First, the analysis uses the tolerance to find the percentiles to calculate. where z is a percentile from the standard normal distribution and t is the tolerance. for example, if the tolerance is 6, then pu = p (z < 3) = 0.99865. if the tolerance is 6, then pl = p (z < −3) = 0.00135. Potential capability is often called the "entitlement" of your process: it ignores differences between subgroups and represents how the process could perform if the shift and drift between subgroups were eliminated. capability indices that assess potential capability include cp, cpu, cpl, and cpk. Use automated capability analysis to evaluate the capability of your process with several methods. with this analysis, you can do the following: automatically determine a reasonable method to estimate capability statistics. determine whether the process is capable of producing output that meets customer requirements. Complete the following steps to interpret a normal capability sixpack. key output includes control charts, normal probability plot, and capability indices. your process should be stable and the original (or transformed) process data should follow a normal distribution.

Process Control Block Powerpoint Presentation And Slides Ppt Example First, the analysis uses the tolerance to find the percentiles to calculate. where z is a percentile from the standard normal distribution and t is the tolerance. for example, if the tolerance is 6, then pu = p (z < 3) = 0.99865. if the tolerance is 6, then pl = p (z < −3) = 0.00135. Potential capability is often called the "entitlement" of your process: it ignores differences between subgroups and represents how the process could perform if the shift and drift between subgroups were eliminated. capability indices that assess potential capability include cp, cpu, cpl, and cpk. Use automated capability analysis to evaluate the capability of your process with several methods. with this analysis, you can do the following: automatically determine a reasonable method to estimate capability statistics. determine whether the process is capable of producing output that meets customer requirements. Complete the following steps to interpret a normal capability sixpack. key output includes control charts, normal probability plot, and capability indices. your process should be stable and the original (or transformed) process data should follow a normal distribution.

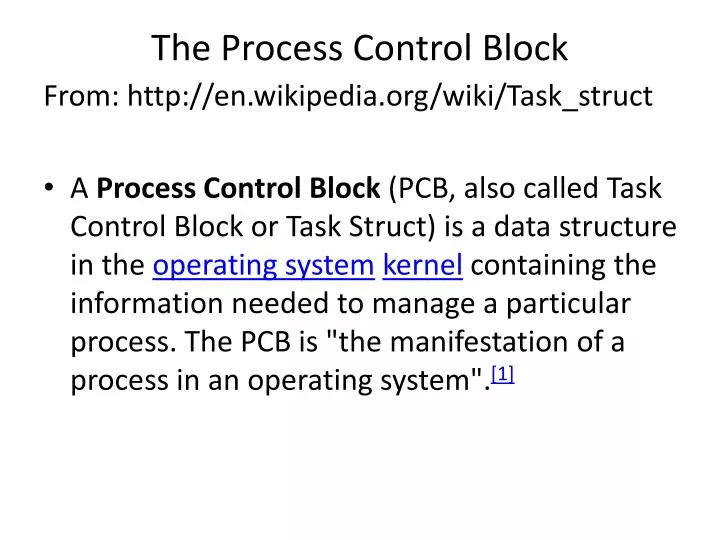

Ppt The Process Control Block Powerpoint Presentation Free Download Use automated capability analysis to evaluate the capability of your process with several methods. with this analysis, you can do the following: automatically determine a reasonable method to estimate capability statistics. determine whether the process is capable of producing output that meets customer requirements. Complete the following steps to interpret a normal capability sixpack. key output includes control charts, normal probability plot, and capability indices. your process should be stable and the original (or transformed) process data should follow a normal distribution.